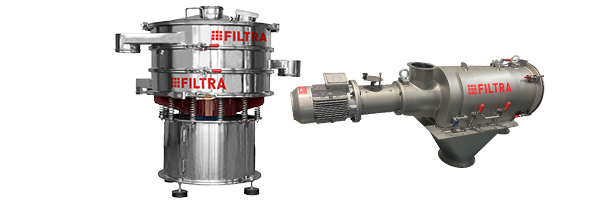

ZEUS – CIRCULAR SIEVE SHAKER

The ZEUS Circular Sieve Shaker is suitable for large production volumes in industrial sieving. It can be used for separation processes for solids in a liquid, for the separation of different granulometries within the same product, in safety sieving for the elimination of foreign bodies, for the homogenization of particles, etc.

It permits a production volume of 100 to 25,000 kg/h, depending on the product, the mesh opening size and the feed flow to the machine. It is suitable for sieving from 36 microns to 25 mm.

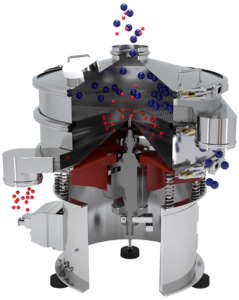

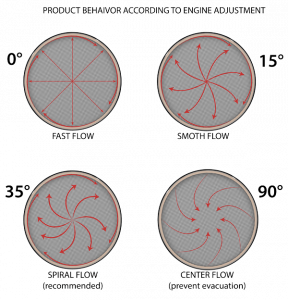

Manufactured from AISI 304 stainless steel (or AISI 316 on request), it features an imbalanced-weight motor which produces a three-dimensional motion which makes the sieving of the product very effective. Adjustment of the imbalanced-weights allows the regulation of product behaviour on the mesh and the sieving speed.

The bottom has a side outlet through which the obtained product can be unloaded. The sieves can be ordered with or without product outlet. In the case of choosing a sieve with outlet, the sieving process can be automated: as the product enters the sieve shaker, it also leaves via the sieve opening.

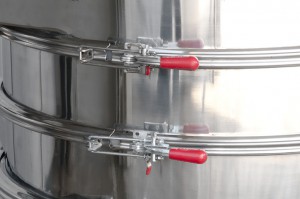

The Circular Sieve Shaker ZEUS model allows up to 4 sieves, with which up to 5 product separations are obtained. The possible diameters are: 550, 800, 1200 or 1500 mm. As an option it can be ordered with fast-closing clamps, lid, viewing windows in the lid and body, and wheels. If the sieve shaker is going to be used in areas classified as being potentially explosive environments then it is manufactured with ATEX materials, and FILTRA will supply the corresponding ATEX certificate. No special floor or foundation is necessary for its installation.

- Allowing 4 sieve levels.

- Separation solid/solid and liquid/solid.

- Cleaning by ultrasonic or cleaning rings.

- Mesh long life

- Liquid and dust free

- Vibrating engine

- Simple maneuvering, main switch stop/start/emergency installed.

- Low consumption.

INCLUDES

- Circular sieve shaker with 1 or more levels of sieving.

- User manual.

- CE declaration of conformity.

OPTIONAL EQUIPMENT

- Lid with product access window.

- Possibility to include product access window in the lid or decks.

- Fast clamp system.

- Sieve cleaning system.

- Ultrasound sieve cleaning system.

- Brusher for cleaning sieves.

- Gaskets, lids and silicone balls.

- Tri clamp, BFM connectors, fast connector without clamp or key

- Machine mounted over wheels.

- Machine with one, two, three or four decks.

- Different surface finishing (AISI304, AISI316, polished, grainy).

- The possibility of manufacture for explosive environments.

- Possibility of customization according to user needs.

3D MOTION

| Model | Voltage (V) | Freq. (Hz) | r.p.m | Power (kW) | Weigth (Kg) |

|---|---|---|---|---|---|

| FTI-0400 | 400-460 | 50-60 | 1500 | 0.3 | 70 |

| FTI-0550 | 0.525 | 100 | |||

| FTI-0800 | 1.1 | 160 | |||

| FTI-1200 | 2.0 | 337 | |||

| FTI-1500 | 2.0 | 460 |

Productivity

| PRODUCT | MESH OPENING | FTI-0550 | FTI-0800 | FTI-1200 | FTI-1500 |

|---|---|---|---|---|---|

| Milk Powder |

400µ | 350 Kg/h | 800 Kg/h | 1.800Kg/h | 2.800Kg/h |

| Orange juice |

1000µ | 1.600 l/h | 3.500 l/h | 8.000l/h | 12.000l/h |

| Species | 600µ | 400 Kg/h | 1.000 Kg/h | 1.500Kg/h | 1.800Kg/h |

| Sweet pepper |

1000µ | 180 Kg/h | 350 Kg/h | 1.000Kg/h | 1.300Kg/h |

| Serum lactic |

50µ | 1.000 l/h | 2.200l/h | 5.000l/h | 7.500l/h |

| Sugar glass |

150µ | 800 Kg/h | 2.000 Kg/h | 3.000 Kg/h | 3.500Kg/h |

| Wheat flour |

300µ | 300 Kg/h | 600 Kg/h | 1.350 Kg/h | 2.100Kg/h |

| High- Density Polyethylene | 3000µ | 600 Kg/h | 1.300 Kg/h | 3.000Kg/h | 4.500Kg/h |

| Ammonium sulfate | 350µ | 400 Kg/h | 900Kg/h | 2.000Kg/h | 3.100Kg/h |

| Toner powder | 100µ | 90 Kg/h | 170 Kg/h | 400Kg/h | 600Kg/h |

| Glass powder | 100µ | 270 Kg/h | 500 Kg/h | 1.300Kg/h | 2.000Kg/h |

| Shredded tire | 1000µ | 300 Kg/h | 650 Kg/h | 1.500Kg/h | 2.200Kg/h |

| Purines | 125µ | 2.000 l/h | 4.000 l/h | 10.000l/h | 15.000l/h |

| PET recycled | 5000µ | 400 Kg/h | 850 Kg/h | 2.000Kg/h | 3.000Kg/h |

| Biofuel oil | 200µ | 800 l/h | 1.600 l/h | 4.000l/h | 6.100l/h |

| Acrylic paint | 80µ | 500 l/h | 1.200 l/h | 2.700l/h | 4.200l/h |

Self Cleaning Rings

Self Cleaning Balls

Self Cleaning Paddels

Window

Ultra Sounds System

Flexible Connectors

FTI-0400

Customized execution of our ZEUS FTI-040 screening machine for the pharmaceutical industry.

ESPIRAL

Spiral for driving products.

FTI-1200

Special production of the ZEUS FTI-1200 with sight glass for visual control.

SEALING ACCESSORY

High performance perimeter sealing sieving fixture.

ANTISTATIC FABRIC SKIRT

The antistatic fabric skirt has as main function the protection of the user, minimizes any risk.

SIGHT GLASSES

Register peephole for screening control.

- Minerals

- Fertilizers

- Plastics

- Metals

- Seeds

- Herbs

- Grains

- Food

- Wood

- Fibres